King/s Solution Corp. / King's Machinery

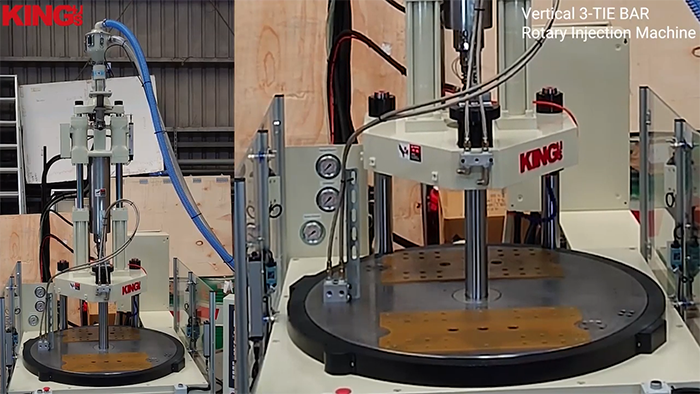

Vertical Rotary 3 Tie-bar Injection Molding Machine

✔️Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put-in, take-out products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production.

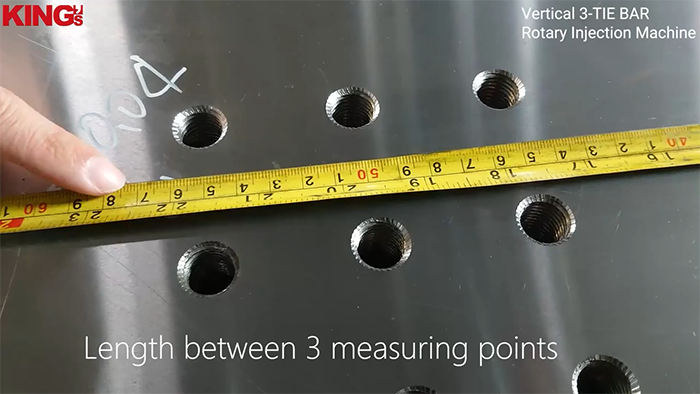

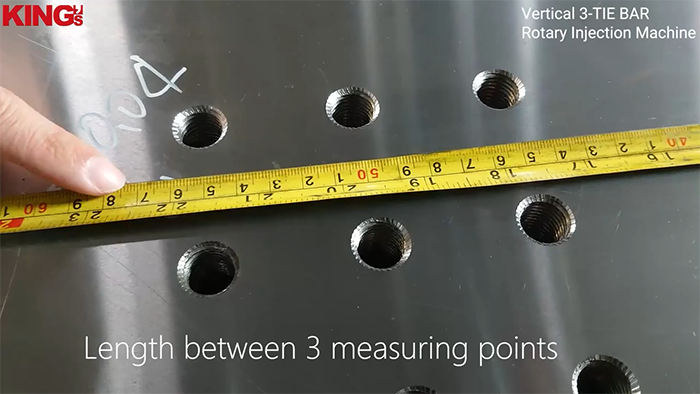

✔️High precision mold platen ( Parallelism/ flatness : 0.02/100 mm), heavy-duty tie-bars, and low-pressure mold clamping work together to greatly extend machine & mold life.

✔️Nitride and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks.

✔️All series adapted Variable pump +PQ valves enable energy savings of 30~50%..

✔️Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life.

✔️Low oil temperature, durable parts, high speed injection, and quiet operation.

✔️Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjustment of machine.

✔️All machine with compact design to resolve the shortage of factory floor-space.

✔️Your best partner in molding Solution

✔️Any idea please contact: +886 - 3 - 3218768 , www.injection.com.tw , [email protected]

FB:https://www.facebook.com/Kingsmachinery/posts/2054984991289023

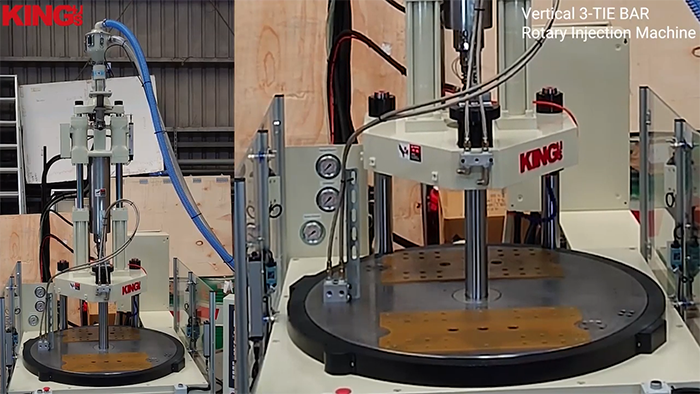

Vertical Rotary 3 Tie-bar Injection Molding Machine

✔️Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put-in, take-out products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production.

✔️High precision mold platen ( Parallelism/ flatness : 0.02/100 mm), heavy-duty tie-bars, and low-pressure mold clamping work together to greatly extend machine & mold life.

✔️Nitride and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks.

✔️All series adapted Variable pump +PQ valves enable energy savings of 30~50%..

✔️Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life.

✔️Low oil temperature, durable parts, high speed injection, and quiet operation.

✔️Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjustment of machine.

✔️All machine with compact design to resolve the shortage of factory floor-space.

✔️Your best partner in molding Solution

✔️Any idea please contact: +886 - 3 - 3218768 , www.injection.com.tw , [email protected]

FB:https://www.facebook.com/Kingsmachinery/posts/2054984991289023